+86-731-83285111

eu@magicglue.net

We have been focusing on producing every drop of glue. The development of stone glue industry standards, more than 300 trademarks and patents, products are exported to Asia, Africa, and Latin, which is the powerful evidence of the leadership position of the MAGPOW. Best choice is generated by comparison. MAGPOW must be your best choice!

[Scope of application]

It is mainly used for the bonding and repair of stone, the double side of the countertop, and also has a good bonding effect on ceramics, metal and concrete.

[performance characteristics]

This product is modified fast curing epoxy stone glue with high bonding strength, fast curing speed, low temperature curable and easy to use. Water, oil and aging resistance.

【Product advantages】

1. Fast curing, 1 hour initial curing positioning under normal temperature conditions;

2. High bonding strength, shear strength after curing is above 10MPa;

3. Excellent resistance to media and aging resistance;

4. The product complies with GB18583, GB30982 standard, EU ROHS directive standard, and belongs to green environmental protection products.

【Instructions】

1. The requirements of bonding surface

(1) The water used for the cleaning of the board should be clean and non-polluting fresh water;

(2)The board to be bonded should be free of impurities such as dust, dirt, sand and oil;

(3) The board to be bonded must be dry and can be dried by drying or naturally drying;

(4)The bonding surfaces of the plates to be bonded must be flat or match each other.

2.Prepare the glue and mix

(1) Mix the rubber in proportion A:B=1:1 (weight ratio) and mix well;

(2)The glue should be used now. After the glue is adjusted, it must be used up within the available time. If the glue exceeds the available time, the glue will be hot.

Phenomenon should be stopped immediately; the more the amount of glue is adjusted, the higher the temperature, the shorter the time that can be used, and the longer it is;

If the amount of sexual adjustment is too large, it should be used separately and quickly;

(3) Do not mix the cover of component A and B. Please cover the cover at any time to avoid absorbing moisture from the air and falling into the ash.

dust;

(4)Always use special toner when grading. The maximum amount of toner is 0.5% of the amount of glue.The colorant will affect the curing speed and bonding strength of the glue;

(5) If the temperature is low, the viscosity of the glue is large, and it is inconvenient to use. It is heated in a water bath of 40-60℃ to make the viscosity smaller, so as to adjust the glue.

3.Spreading the glue

(1)The ideal temperature for sheet metal coating is 25-35 ° C, and the air humidity is less than 75%;

(2)Use a scraper to scrape the glue and apply the glue evenly on the plate. According to the looseness of the material, single or double can be used.

Topcoating;

3)The thickness of the glue should be appropriate. Under normal circumstances, the thinner the rubber layer, the smaller the defect, the smaller the deformation, the smaller the shrinkage, and the smaller the internal stress.The higher the bonding strength, the thickness of the adhesive layer is generally controlled to be 0.2-0.3 mm on the premise of ensuring no glue shortage.

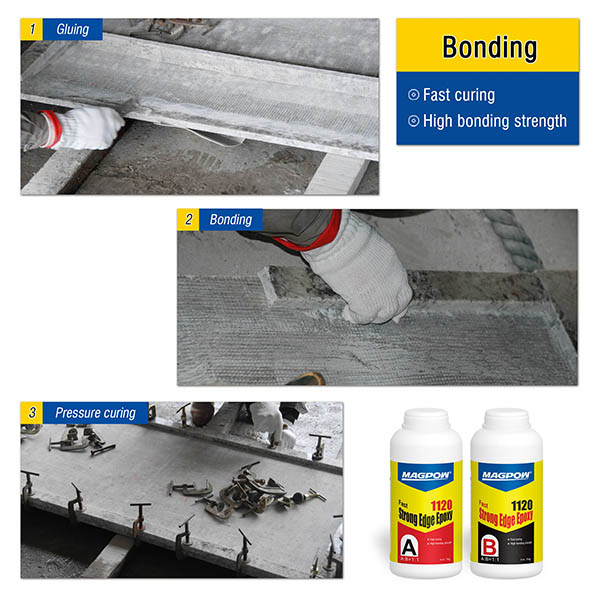

4. Bonding, pressure

(1) Bonding the plates, reciprocating the plates by hand and applying pressure to remove the air between the plates, so that the glue is fully filled, it is necessary to

Have proper glue outflow;

(2)Align and press the plate up and down, the pressure should be evenly distributed, and the pressure method can be based on the actual situation.

And set.

5.Curing

( 1)After standing under pressure, it can be solidified. It can be loosened after being cured at room temperature (25℃) for 1-2 hours. After 24 hours, it can be put into the next process.

(2)The construction temperature should not be lower than 5℃. When the ambient temperature is lower than 15℃, the curing speed of the glue will be significantly slowed down.

Heating is used to promote curing; when the temperature is low in winter, the bonded sheets can be placed in a baking room at 50-60℃.

Heat evenly for 2-3 hours, then naturally cool to room temperature to enter the next process;

(3)Recommended process: After the adhesive layer is cured at 25-35℃ for 2-4 hours, the bonded sheet is placed in the dry room,After that, the temperature is raised to 60℃for 1 hour, and then the temperature is raised to 80℃for 1 hour, and then dried in the room.Cool to room temperature and relieve pressure.

(4) Do not move the sheet before the glue is initially cured.

6.clean up

Before the glue is uncured, please use special cleaning agent to clean it and use it. The glue on the edge of the stone is not solidified.

Please scrape off the excess glue before.

【Protective measures】

Due to the individual differences of the operators, the glue may cause allergies to certain parts of the skin, but the product meets the requirements.

GB18583-2008 "Limits of harmful substances in interior decoration materials adhesives", GB30982-2014 "Building adhesives have the national mandatory standard for harmful substances is an environmentally friendly product and has no other harm to the human body. I suggest that your company is using composite when glue, do the following necessary protection:

(1)Use in a well ventilated environment;

(2) equip with necessary protective clothing, protective gloves and protective masks;

(3)Avoid contact with the skin directly. If you accidentally touch the skin, use soapy water to clean it.

(4) Before adjusting the glue, first open the cover of component B, let the free low molecular substances evaporate, and then take the glue and adjust the glue;

(5)If there is an allergic reaction, employees should change jobs.

【Precautions】

1. There are many reasons for the unfavorable bonding effect. Please note:

(1)The plate is not dry enough or the air humidity is too high, and the moisture content of the plate causes the water content of the plate to be high;

(2)The glue A/B component is not adjusted according to the specified ratio;

(3)Leave a dead angle or insufficient stirring time to cause uneven mixing of the glue;

(4)The combination of the two components of A and B causes the curing reaction to occur early;

(5)After the glue is evenly mixed, it is not used within the effective time.

(6) Insufficient amount of glue or uneven coating results in lack of glue;

(7) No misalignment during bonding to eliminate air formation defects between sheets;

(8)insufficient pressure to cause the glue layer to be too thick or excessive pressure to cause lack of glue;

(9)Disturbed during curing.

2. When the temperature is low in winter, the product may crystallize and agglomerate. The glue can be melted and melted without affecting performance.

3. The glue that is not fully cured on the skin or clothes can be wiped clean with cloth dampened alcohol before uncured, and then washed with soapy water;

If you accidentally enter your eyes, rinse with plenty of water and apply immediately. If you accidentally swallow, do not induce vomiting.Clear or milk, seek medical attention immediately.

【Technical data】

|

No |

Item |

Technical data | |

|

1 |

Appearance |

Component A |

White paste fluid |

|

Component B |

Beige paste fluid | ||

|

2 |

Mixing ratio(A∶B) |

1∶1 | |

|

3 |

Pot life(25℃,min) |

10-15 | |

|

4 |

Initial curing time(25℃,h) |

1-1.5 | |

|

5 |

Tensile shear strength(RT48h,MPa) |

≥10.0 | |

|

Temperature(℃) |

Operation time (min) |

initial curing time(h) |

|

5-10 |

20-30 |

3-5 |

|

10-20 |

15-20 |

2-3 |

|

20-30 |

10-15 |

1-2 |

|

30-40 |

5-10 |

0.5-1 |

[Storage and Transportation Packaging]

1. The product is sealed and stored in a cool, dry and ventilated warehouse at a storage temperature of 5-40 ° C. This product is manufactured from the date of production.

The warranty period is one year, and the expiration can be continued after passing the inspection.

2. This product is a corrosive product. It is kept away from heat and fire during transportation to prevent sun and rain. During transportation, loading and unloading

It should be handled gently, and it is forbidden to roll, bump, press, invert and side.

3. Packing specification: 2Kg / set (12Kg / piece), iron hall packaging.

【Important Notes】

1. Due to the ever-changing material of the material to be bonded, material changes may affect the bonding effect. For this purpose, use a lot

Be sure to try it before using it. After confirming the pass, use it in large quantities.

2. Our company solemnly promises that our products are strictly produced in accordance with the company's standards. Our company is only responsible for the products themselves, not for customers.

The process is responsible.

3. Our company strictly implements ISO9001 quality system and ISO14001 international environmental certification system to provide customers with high quality and qualified.

The product. The technical opinions provided by our company, whether verbally, in writing or on the experiment, are sincere, but not

Guarantee. Users should read the instructions carefully before using the experiment and conduct experiments to verify that it is suitable for the proposed process and

use.

4. The company cannot control the quality of storage and transportation, the environment at the time of use, and the operation process during use, thus causing quality problems caused by improper construction of customers.

The problem and the associated losses are the responsibility of the user and are not the responsibility of the company.

5. No employee of the company has the right to change or waive the above terms!

[Executive Standard]

National Mandatory standard:GB24264-2009

[Guangdong] Conley Stone Group Quality is a solid foundation for cooperation

[Hubei] Xinyi Stone Factory signed a cooperation contract immediately after trialing samples of stone back mesh glue

[Jiangxi] Use MAGPOW Stone Back Glue, Stone Breakage Rate Drops

[Shandong] Gaoshi Stone Group once again purchases stone adhesive by telephone